Design, automation, and project management from an engineer/builder. Railroad, mining, sawmill, winery — we deliver the results you expect.

PLC programming across Rockwell, Mitsubishi, Siemens, and Omron. HMI/SCADA design, CNC integration, and process control systems.

Computer vision for quality inspection and defect detection. Predictive maintenance models integrated with PLC/SCADA systems. Embedded AI on NVIDIA Jetson edge devices for shop-floor deployment.

3D CAD modelling and detailed drawings in Inventor, SolidWorks, CREO, and AutoCAD. Tanks, piping, structural steel, sheet metal, and custom fabrication.

Fluid system design for fuel storage, water distribution, wastewater treatment, and process piping. Tank design and API 650 inspection coordination.

Mechanical services and design to ANSI 51/169 for Okanagan wineries and BC craft breweries: tanks, conveyors, water distribution, glycol systems, process piping, and wastewater.

Sawmill and planer mill engineering: log scanning, debarker, edger, kiln controls, conveyors, PLC migration, and production optimization.

Formed steel welded buildings for housing electrical switchgear, process equipment, and controls. Designed to ship and install anywhere.

CNC lathes, hydraulic presses, conveyors, material handling cranes, and NDT inspection systems. Turnkey design and integration.

Full lifecycle delivery from RFQ through installation and commissioning. We coordinate trades, manage budgets, and keep your project on track.

View All Services →DM Engineering Ltd is a mechanical engineering consultancy based in the Southern BC serving clients across BC, Alberta, and the USA. Founded by Devon Murray, P.Eng, the firm brings over 15 years of hands-on experience across railroad infrastructure, sawmill operations, industrial automation, pharmaceuticals, fuel storage, and winery and brewery systems.

With expertise gained from a thick coating of hydraulic fluid and gear oil, our ability to solve real problems, right now, takes us beyond our competition. Devon received another 5 years of trades experience as a welder, electrician, and carpenter alongside his engineering career — which means designs that appreciate manufacturability, maintainability, ease of installation, along with budgets that reflect reality.

We stay actively licensed to practice professional engineering in BC, Alberta, and the USA. Whether you need strong oversight for an operation, thorough engineering analysis or full-scope mechanical design, we will be there.

Automated dust suppression applicator system for coal handling operations.

Complete maintenance facility with sub-floor pit, DAF wastewater treatment, wash systems, and exhaust extraction.

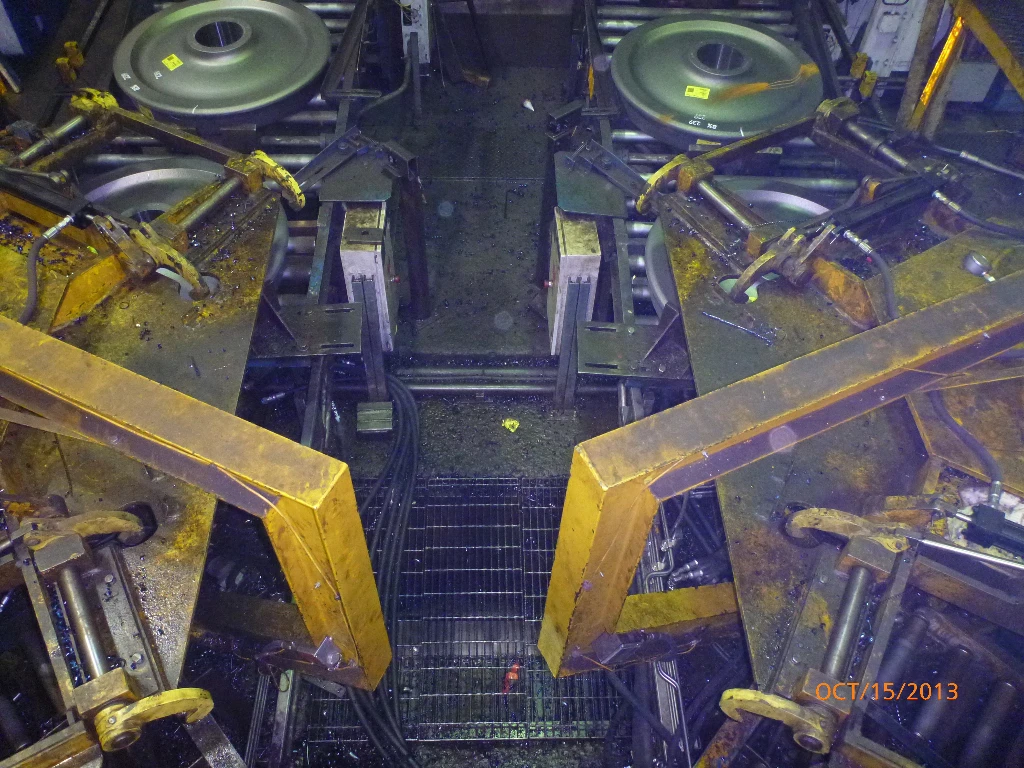

Heavy equipment for dismount, axle wash, CNC lathe, and remount of railroad wheelsets. PLC upgrades from relay logic.

Replacement of 1M litre diesel tanks to API 650 with cathodic protection. Site remained operational throughout.

Hydraulic drop table systems for railcar wheelset servicing. Custom designed and installed across multiple sites.

PLC programming, HMI/SCADA design, CNC integration, and custom software across multiple platforms and industries.

Wheelset remanufacturing, drop tables, fuel systems, and maintenance facility design across Western Canada and the USA.

Process control, fluid transfer, fuel storage, modular buildings, and equipment design for mine sites and processing plants.

Sanitary piping, glycol systems, crush pad equipment, and full mechanical scope for Okanagan wineries and BC craft breweries.

Controls upgrades, conveyor systems, kiln optimization, and PLC migration for lumber and planer mill operations.

Fuel storage to API 600, dispensing systems, cathodic protection, and secondary containment for petroleum operations.

CNC systems, hydraulic presses, material handling, conveyor lines, and automated inspection stations.

Modular switchgear buildings, medium voltage enclosures, HVAC systems, and electrical distribution infrastructure.

We are always interested in hearing about new challenges.

We design, program, and commission control systems for manufacturing, process, and building automation. From upgrading legacy relay logic to designing new turnkey PLC systems with operator interfaces and reporting.

Programming experience spans Rockwell (Allen-Bradley), Mitsubishi, Siemens, Omron, and Phoenix Contact platforms using Ladder Logic and Structured Text. We also develop custom software tools in C++, Python, and C#.NET for production support, data logging, and CAD automation.

We integrate machine learning and computer vision into industrial and manufacturing environments. This is not cloud-based AI hype — it is embedded intelligence running directly on your equipment. Think of it as another control system that happens to use cameras and neural networks instead of proximity sensors and relay logic.

Our work includes vision systems for quality inspection and defect detection on production lines, predictive maintenance models that integrate with existing PLC and SCADA infrastructure, and edge AI deployed on NVIDIA Jetson hardware. We write in high level langauges, like Go, Python and C++, that handle the vision stack to integrate with your control systems or loop back to train an AI model for a custom local implementation.

3D CAD modelling and detailed engineering drawings for fabrication, construction, and installation. We work in Inventor, SolidWorks, CREO, and AutoCAD depending on the project requirements and client preference.

Our design approach prioritises build-ability: parts that can be reused across assemblies to reduce part count, sheet metal designed for in-house cutting and bending, and assemblies that cannot be installed incorrectly.

Fluid system design for fuel storage, water distribution, wastewater treatment, and industrial process applications. We have designed and commissioned systems ranging from small glycol loops to 1-million-litre diesel tank farms built to API 650.

Our approach covers the full system: tank design and placement, pump selection and sizing, piping layout, valve and instrumentation specification, and integration with control systems for automated operation.

Purpose-built mechanical systems for Okanagan wineries and BC craft breweries. We bring the same engineering rigour used in heavy industrial facilities to the unique requirements of beverage production: food-grade materials, sanitary design, temperature-critical processes, and facilities that need to look good while they work hard.

Whether you are building a new facility, expanding production, or upgrading aging infrastructure, we can design and manage the mechanical scope from concept through commissioning.

PLC control system upgrades for sawmill and planer mill optimization. We work with log scanning and sort systems, debarker controls, headrig and resaw optimization, trimmer and edger controls, kiln drying systems, and sorter/tally integration. Our experience with Rockwell/Allen-Bradley platforms — including ControlLogix and legacy PLC5 migration — aligns directly with the requirements of modern BC Interior lumber operations.

Whether you are upgrading legacy controls on existing equipment, integrating new scanning and optimization technology, or designing material handling and conveyor systems, we bring the same hands-on commissioning approach we apply across all our industrial projects.

Custom-built modular buildings using formed steel shell and steel stud construction. Typical modules are 50’ x 14’ and include HVAC, compressed air, and electrical distribution. Assembled in-house and shipped by truck or barge to site fully complete and ready to operate.

We have designed modular enclosures for medium voltage switchgear (15/25 kV), delivered to heavy industrial clients around the globe.

Turnkey design and integration of manufacturing equipment: CNC lathes, hydraulic press-on/off machines, material handling cranes and carts, NDT inspection stations, and conveyor systems. We handle the mechanical design, controls integration, and on-site commissioning.

These are purpose-built systems designed for the specific workflow of your facility. We have delivered equipment across Canada and the USA for railroad, remanufacturing, and heavy industrial operations.

We manage mechanical and multidisciplinary projects from quotation through installation and commissioning. This includes developing RFQs, coordinating contractors across welding, electrical, millwright, painting, and civil trades, and maintaining transparency with clients on timeline, budget, and deliverables.

Our principal engineer has hands-on experience as a welder, electrician, and carpenter. That means realistic schedules, accurate cost estimates, and the ability to bridge the gap between engineering drawings and shop floor reality.